LIHYP – LINKING HYDROGEN POWER POTENTIALS

PROJEKTE

Quelle: NWN/Rainer Jensen

Quelle: NWN/Rainer Jensen

Internationale Kooperationen sind der einzige Weg nach vorne für die Energiewende, die dringlicher denn je geworden ist. Durch die Bündelung von Willenskraft, Wissen und Best Practices im Rahmen des LIHYP-Projekts werden die notwendigen Werkzeuge geschaffen, die effektiv zu einer nachhaltigen, sicheren und autonomen Energiezukunft beitragen werden. Europäische Zusammenarbeit von seiner besten Seite!

LIHYP – Linking Hydrogen Power Potentials

„Zusammenführung von Akteuren zum Aufbau einer regionalen Wasserstoffwirtschaft in der Nordseeregion“ – Das ist das Motto des Projekts „LIHYP“: In den Niederlanden, Belgien, Dänemark, Frankreich und Deutschland sollen verschiedene Pilotprojekte zur Nutzung von Wasserstoff durchgeführt werden, z. B. Wasserstoff-Lastenfahrräder, wasserstoffbetriebene Güterzüge, Wasserstoff-Busstationen und Living Labs. Außerdem wird eine Wasserstoffplattform für die Nordseeregion eingerichtet, um die relevanten Interessengruppen zu vernetzen, und es wird eine solide Datenbank für Nachfrage, Produktion und Angebot von Wasserstoff geschaffen.

LIHYP schließt diese Lücke, indem es eine intensive Zusammenarbeit zwischen den regionalen Akteuren entlang der Nordsee fördert und sie über die gesamte Wasserstoff-Wertschöpfungskette hinweg für den Austausch von Know-how und die Zusammenarbeit zwischen Entscheidungsträgern, Umsetzern und Investoren verbindet.

Planmäßig soll das gesamte Projekt bis Januar 2027 laufen. Die Roadmap, die fürs Gesamtprojekt erstellt wird, hat einen Zeithorizont bis 2030.

Arbeitspakete

WP 1 – Wegweisende Zusammenarbeit im Bereich Wasserstoff: Start der NSR-Plattform

WP 2 – LIHYP-Pilotaktivitäten: Innovation mit H2-Demonstratoren vorantreiben

WP 3 – Harmonisierung der Vorschriften für die Integration von grünem Wasserstoff

WP 4 – Verwirklichung interregionaler dynamischer H2-Roadmaps

Teilprojekte

Gent, Belgien: Living Lab Belgium

Groningen, Niederlande: Hydrogen Valley Airport – Groningen Airport Eelde

Oldenburg, Deutschland: Development of a local Energy HUB for city cargo

Handest Hede, Dänemark: Hydrogen Refueling Station connected directly Wind/PV site

Bentheim, Deutschland: Hydrogen driven freight train in the cross-border region DE/NL

Als Niedersächsisches Wasserstoffnetzwerk gehen wir hier genauer auf die niedersächsischen Projekte ein.

Entwicklung einer lokalen Energiedrehscheibe für die innerstädtische Logistik

Quelle: LIHYP

Quelle: LIHYP

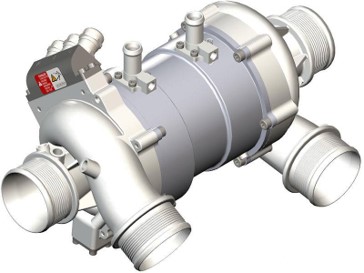

Brennstoffzellen-Lastenräder für die innerstädtische Logistik ermöglichen längere Einsatzzeiten und Vorteile für den Betreiber. Dieser Nachweis wird im Projekt als technische Demonstration untersucht. Dabei werden sowohl die Versorgung mit grünem Wasserstoff als auch die Bereitstellung untersucht. Darüber hinaus werden Einflüsse der Kraftstoffqualität und deren Befüllung der Tanks für den Einsatz im Fahrzeug konzeptionell und prototypisch umgesetzt. Dabei müssen sowohl behördliche Vorschriften als auch arbeitsrechtliche Vorgaben zum Umgang mit Wasserstoff entsprechend umgesetzt werden.

Neben der Reduzierung der Emissionen und den neuen logistischen Vorteilen soll das Pilotprojekt auch anderen Regionen als Blaupause empfohlen werden können. Zu diesem Zweck wird im Rahmen des Projekts eine angemessene Kommunikation und Präsentation des Konzepts gegenüber interessierten Kreisen gefördert.

Wasserstoffbetriebener Güterzug im Grenzgebiet DE/NL

Quelle: AdobeStock_9377671

Quelle: AdobeStock_9377671

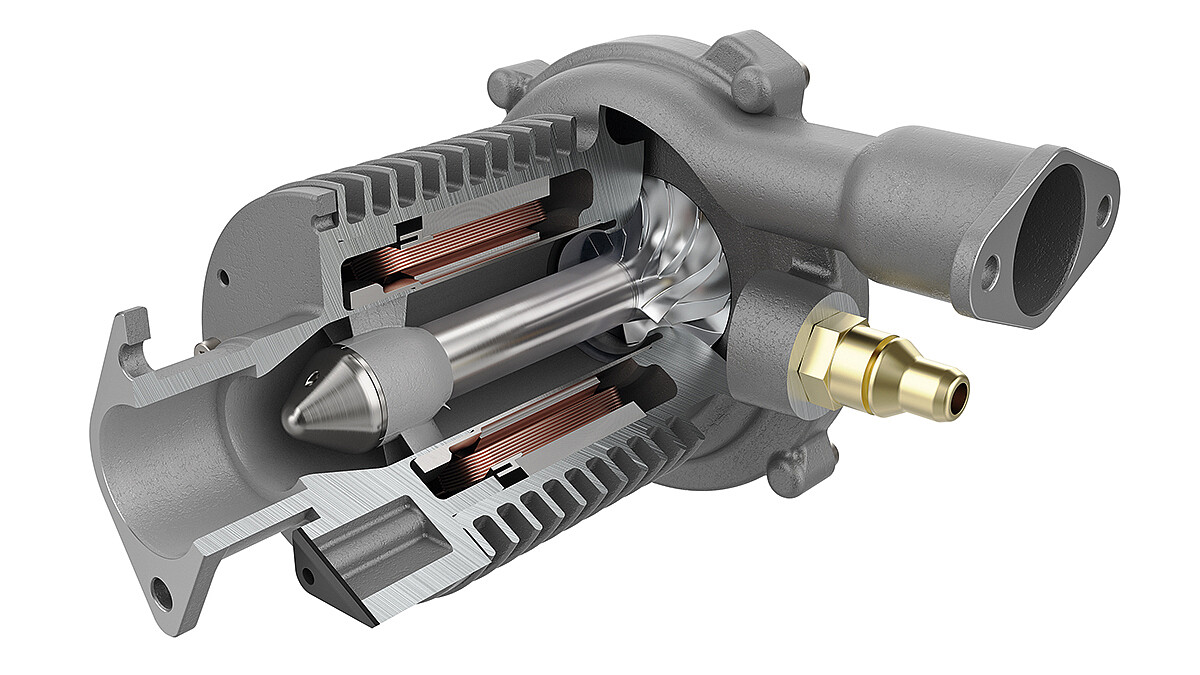

Der Transport von Gütern ist immer mit dem Ausstoß von Treibhausgasen verbunden. Es gibt unterschiedliche Ansätze, diese Emissionen zu reduzieren, beispielsweise die Kombination verschiedener Transportlösungen (Zug, LKW, Binnenschiffe, Flugzeuge) oder den Einsatz „grüner“ Antriebstechnologien wie batterieelektrische Fahrzeuge.

Obwohl der Gütertransport mit der Bahn im Allgemeinen einen geringen CO2-Fußabdruck hat, nutzen Güterzüge häufig Dieselmotoren, da nicht alle Gleise und insbesondere Güterbahnhöfe nicht vollständig elektrifiziert sind – und grenzüberschreitender Transport selbst auf vollständig elektrifizierten Gleisen nicht immer möglich ist. Für den treibhausgasfreien Gütertransport auf der Schiene sind daher – insbesondere im internationalen Kontext – alternative Antriebslösungen erforderlich.

Doch was ist nötig, um einen grenzüberschreitenden Güterzug mit Wasserstoff zu betreiben? Was sind die technologischen Herausforderungen, wie ist die Wasserstoffversorgung am sinnvollsten und welche Synergien lassen sich in der Region generieren?

Über das Vorhaben hinaus werden die Ergebnisse dazu beitragen, dass weitere Projekte einfacher umgesetzt werden können und erste Schritte zu CO2-neutralen Güterzügen unternommen werden können.

Das Projekt wird im Rahmen des INTERREG-Nordseeprogramms finanziert und ist somit CO-Finanziert von der Europäischen Union.

Mehr Informationen auf der Website.

Neueste Kommentare