Clean Hydrogen Coastline

PROJEKTE

Quelle: EWE

Quelle: EWE

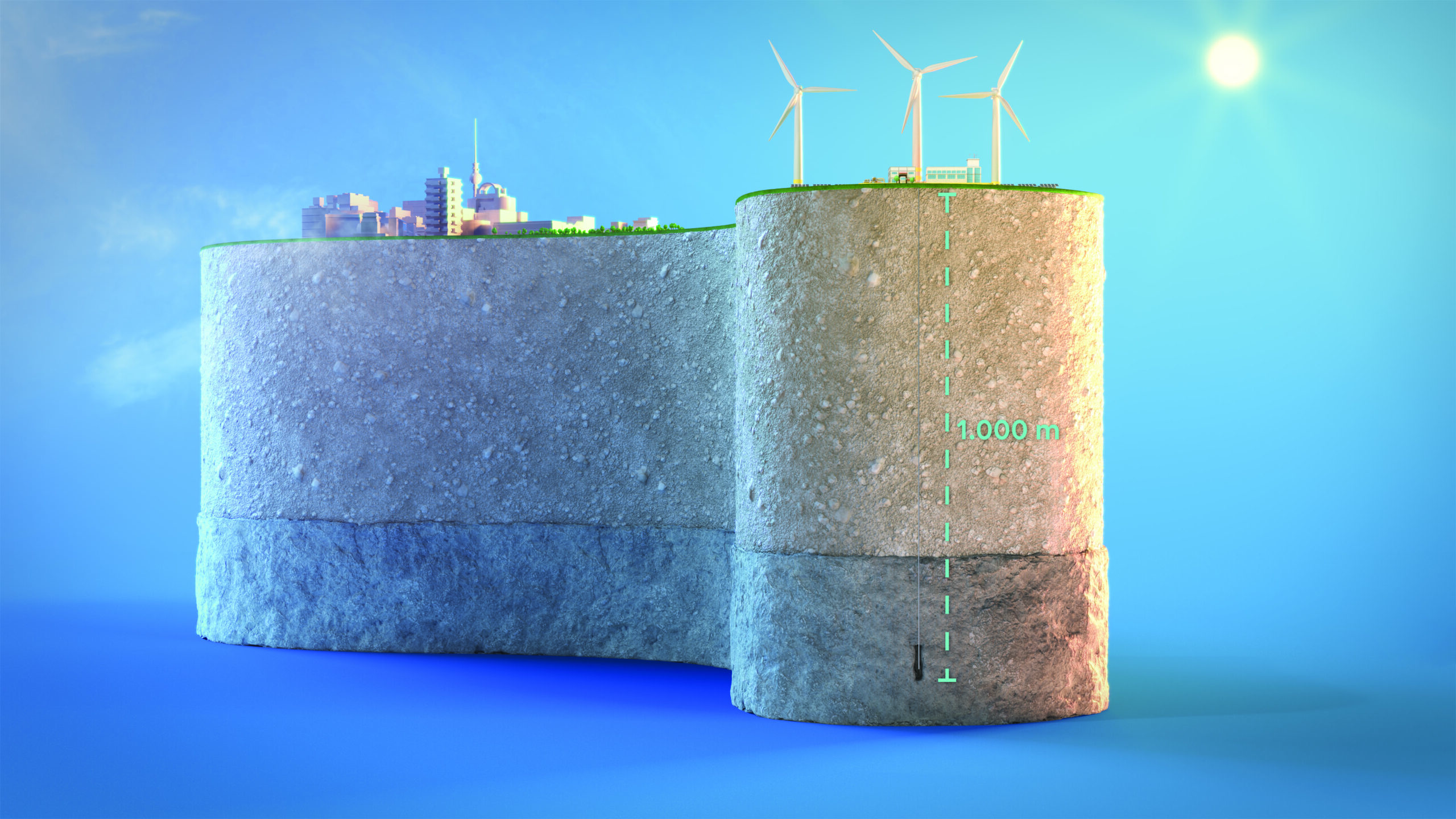

Etwa 400 Megawatt Elektrolysekapazität soll bis 2026 im Projekt „Clean Hydrogen Coastline“ in der Region Nordwest aufgebaut werden. Bildquelle: ©EWE

Clean Hydrogen Coastline

Der deutschen Nordseeküste kommt beim Aufbau einer bundesweiten Wasserstoffwirtschaft eine besondere Bedeutung zu. Aufgrund des hohen Angebots von erneuerbaren Energien kann Wasserstoff in der Region nicht nur erzeugt, sondern auch gespeichert, über bestehende Strom- und Gas-Infrastruktur in das Energiesystem eingebunden, oder unmittelbar vor Ort genutzt werden. Das „Important Project of Common European Interest“ (kurz IPCEI) „Clean Hydrogen Coastline“ soll dazu beitragen, die Wasserstoffwirtschaft in der Region Nordwest auf- und auszubauen.

News (25.07.2024): Energieversorger EWE vergibt Auftrag für Wasserstoff-Großprojekt in Emden an Siemens Energy

Wie der Energieversorger EWE bekanntgab, wird Siemens Energy bei dem Bau einer der größten Wasserstoff-Erzeugungsanlagen Europas in Emden unterstützen. Die gesamte Erzeugungsanlage bestehend aus Elektrolyse sowie notwendiger Peripherie – wie beispielsweise Verdichter und Kühlsysteme – hat über die Lebensdauer eine mittlere Leistungsaufnahme von circa 320 Megawatt. Der Energietechnologie-Konzern wird ein 280-Megawatt-Elektrolysesystem als Kernstück der Anlage liefern. Im Jahr 2027 soll die Anlage in Emden in Betrieb gehen und dann pro Jahr rund 26.000 Tonnen grünen Wasserstoff für unterschiedliche Anwendungen bereitstellen. Mehr dazu

News (15.02.2024): IPCEI-Projekte: Europäische Kommission genehmigt Förderungen

Wie die Europäische Kommission bekanntgab, wurde die dritte IPCEI-Runde unter dem Titel „Hy2Infra“ nun genehmigt. Hierdurch dürfen die Mitgliedsstaaten öffentliche Mittel in einer Höhe von bis zu 6,9 Milliarden Euro bereitstellen. In der aktuellen Runde sind 32 Unternehmen im Rahmen von 33 Projekten beteiligt – zu denen auch das Projekt Clean Hydrogen Coastline gehört. Mehr erfahren

News (16.01.2024): Wasserstoff-Kooperation zwischen EWE und ArcelorMittal Bremen

Wie EWE und der Stahlhersteller ArcelorMittal gestern bekanntgaben, haben die beiden Unternehmen die nächste Wasserstoff-Kooperation beschlossen. Demnach soll EWE grünen Wasserstoff nach Bremen liefern, um dort die Dekarbonisierung der Stahlindustrie zu ermöglichen. Im Zentrum des Vorhabens steht eine 320-Megawatt Erzeugungsanlage, die in Emden installiert werden soll und ab voraussichtlich 2028 grünen Wasserstoff produziert.

Ausgangspunkt für dieses Vorhaben ist das Großprojekt „Clean Hydrogen Coastline“. In dem Projekt wird an der Nordseeküste eine Wasserstoffwirtschaft mit Erzeugungs-, Speicher- und Transportmöglichkeiten aufgebaut. Der Wasserstoff soll schließlich in der Industrie zum Einsatz kommen – neben ArcelorMittal Bremen z.B. auch in Salzgitter bei der Salzgitter AG. Mehr erfahren

News (24.08.2023): Kooperation von EWE AG und Georgsmarienhütte GmbH!

Grüner Stahl aus Georgsmarienhütte – EWE AG und Georgsmarienhütte GmbH geben Wasserstoff-Kooperation bekannt für eine komplett klimaneutrale Stahlherstellung ab 2039!

Ab 2039 soll der Stahl aus Georgsmarienhütte klimaneutral hergestellt werden. Dafür liefert der Kooperationspartner EWE den grünen Wasserstoff aus Erzeugungsanlagen im Nordwesten Deutschlands.

Niedersächsischer Ministerpräsident Stephan Weil dazu: „Ich freue mich sehr, dass EWE und Georgsmarienhütte sich darauf verständigt haben, den Aufbau der Wasserstoffindustrie deutlich zu beschleunigen. Für die neuen klimafreundlichen Prozesse werden große Mengen erneuerbarer Energie und grünen Wasserstoffs benötigt. Niedersachsen bietet gerade in diesen Bereichen einzigartige Standortvorteile: viel Windenergie auf Land und auf See, wichtige Seehäfen zum Import und zur Verteilung von grünem Wasserstoff und großvolumige unterirdische Formationen zur Speicherung von Wasserstoff. Gerade die Georgsmarienhütte geht einen großen Schritt in Richtung Nachhaltigkeit. Die Stahlindustrie bildet die Grundlage vieler Wertschöpfungsketten und wird mit diesem Leuchtturmprojekt dauerhaft Arbeitsplätze sichern. Mit dieser wegweisenden industriellen Transformation werden EWE und die GMH Gruppe signifikant zum Erreichen der Niedersächsischen und damit auch deutschen und europäischen Klimaschutzziele beitragen.“

News (04.05.2023): EWE und Salzgitter AG wollen beim Thema Wasserstoff kooperieren!

Am 04.05.2023 haben die Salzgitter AG und der Versorger EWE in Salzgitter eine Absichtserklärung unterzeichnet, die eine Kooperation der beiden Unternehmen beim Thema Wasserstoff vorsieht. So will EWE grünen Wasserstoff erzeugen und nach Salzgitter liefern, den die Salzgitter AG dann für die klimafreundliche Stahlerzeugung im Rahmen des Projekts SALCOS® einsetzt. Die Absichtserklärung wurde von den Vorstandsvorsitzenden Stefan Dohler (EWE) und GUnnar Groebler (Salzgitter AG) im Rahmen des Handesblatt Wasserstoff-Gipfels unterzeichnet.

Im IPCEI „Clean Hydrogen Coastline“ wollen die Industriepartner ArcelorMittal, EWE, Gasunie, swb und Tennet in der Region Nordwest 400 Megawatt Elektrolysekapazität bis zum Jahr 2026 aufbauen. Hierzu gibt es verschiedene Projekte, die bei der Umsetzung helfen sollen.

- Im Teilprojekt 1 „Elektrolyse Ostfriesland“ will EWE in Emden eine 320-Megawatt-Elektrolyseanlage errichten und damit Wasserstoff im industriellen Maßstab produzieren. Laut EWE könnte in Emden bereits im Jahr 2028 Wasserstoff aus erneuerbaren Energien erzeugt werden.

- Im Teilprojekt 2 „Elektrolyse Bremen“ will EWE ebenfalls einen Elektrolyseur bauen, allerdings in der Hansestadt Bremen. Der grüne Wasserstoff aus dem 50-Megawatt-Elektrolyseur soll – wie der Wasserstoff aus Emden – u. a. für die klimaneutrale Stahlproduktion genutzt werden. Geplant ist beispielsweise die Lieferung von Wasserstoff zum Bremer Standort von ArcelorMittal, zu der Salzgitter AG oder zu der Georgsmarienhütte.

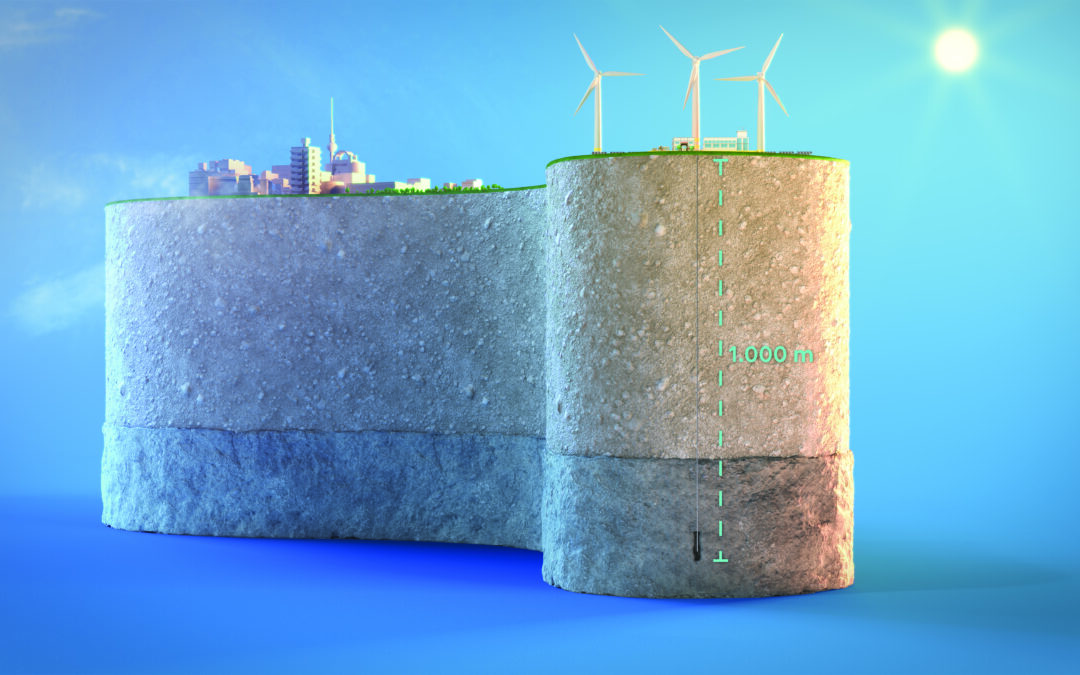

- Im dritten Teilprojekt „Speicher Huntorf“ plant EWE die Anbindung der Wasserstoffinfrastruktur an seinen Kavernenspeicher in Huntorf. So ist vorgesehen, einen unterirdischen Erdgasspeicher und obertägige Anlagen für die Wasserstoffspeicherung umzurüsten. Wichtige Erkenntnisse soll das Forschungsvorhaben HyCAVmobil von EWE bringen, in dem das Unternehmen in Rüdersdorf bei Berlin Wasserstoff in deutlich kleinerem Maßstab in Kavernenspeicher einspeichert.

- Im Rahmen des Teilprojekts 4 „H2-Pipeline-Infrastruktur Nordwest“ soll die Wasserstoff-Infrastruktur im Nordwesten optimiert werden. Durch den Bau und die Umstellung von mehreren Pipeline-Abschnitten wird der Anschluss wichtiger Wasserstoff-Abnehmer und -Speicher an das zukünftige europäische Wasserstofftransportnetz hergestellt.

Durch die vielfältigen Anknüpfungspunkte von Clean Hydrogen Coastline, beispielsweise mit den niederländischen Partnern, aber auch mit Vorhaben in Hamburg und Nordrhein-Westfalen, bieten sich umfangreiche Potenziale für ein europäisches IPCEI. Damit können die Partner einen entscheidenden Schritt machen, um ein wichtiger Baustein einer zukünftigen europäischen Wasserstoffwirtschaft zu werden. Ziel des Projektes ist vor allem die Einbindung von Wasserstoff in bestehende Energieinfrastrukturen.

Partner

ArcelorMittal ist ein internationaler Stahlproduzent mit einem Produktionsvolumen von sieben Millionen Tonnen Rohstahl (2019), der deutschlandweit rund 9.000 Angestellte beschäftigt.

Logo: © ArcelorMittal

Mit rund 9.100 Mitarbeiterinnen und Mitarbeitern ist die EWE AG eines der größten Versorgungsunternehmen Deutschlands, das sich im Bereich Wasserstoff auf entsprechende Infrastruktur fokussiert.

Logo: © EWE AG

TenneT TSO GmbH ist ein Übertragungsnetzbetreiber mit einer Netzlänge von 24.000 Kilometern und ca. 5.700 Beschäftigten.

Logo: © TenneT TSO GmbH

Die Gasunie Deutschland GmbH & Co. KG ist als Fernleitungsnetzbetreiber für ein rund 4.300 Kilometer langes Fernleitungsnetz verantwortlich.

Logo: © Gasunie Deutschland

Die swb AG ist ein regionales Versorgungsunternehmen für Bremen und Bremerhaven mit rund 2.255 Beschäftigten.

Logo: © swb AG

Bleiben Sie informiert – mit unserem Newsletter „NWN direkt…“

Sie möchten über diese und andere spannende Wasserstoff-Projekte aus Niedersachsen informiert bleiben? Dann melden Sie sich bei unserem Newsletter an!

Neueste Kommentare