Importstrategie für Wasserstoff

PROJEKTE

Quelle: AdobeStock_192820721

Quelle: AdobeStock_192820721

Um ausreichend Wasserstoff für den Wasserstoff-Hochlauf zur Verfügung zu haben, ist Deutschland auf Wasserstoff-Importe angewiesen.

Importstrategie für Wasserstoff und Wasserstoffderivate

Trotz zahlreicher Projekte, die zum Aufbau großer Elektrolyse-Kapazitäten in Deutschland und speziell in Niedersachsen beitragen, wird Deutschland in Zukunft auf Wasserstoff-Importe angewiesen sein, um den steigenden Wasserstoffbedarf für die Industrie, die Mobilität und den Kraftwerkssektor zu decken. Um diesen Prozess möglichst strukturiert anzugehen, wurde nun von der Bundesregierung die Importstrategie für Wasserstoff und Wasserstoffderivate vorgelegt.

Die Bundesregierung geht im Rahmen der nun vorgelegten Importstrategie von einem Wasserstoff- bzw. Wasserstoffderivat-Bedarf von 95-130 TWh im Jahr 2030 aus, der vor allem der Stahlindustrie, der Grundstoff- und Petrochemie, in der Mobilität (insbesondere Schiffs- und Luftverkehr) sowie im Kraftwerkssektor benötigt wird. Der Bedarf soll im Jahr 2045 auf 360-500 TWh für Wasserstoff und 200 TWh für Derivate steigen.

Da der Bedarf nicht allein durch die inländische Produktion gedeckt werden kann, müssen nach Prognose der Bundesregierung ca. 50-70 % des Bedarfs importiert werden. Über eine entsprechende Importstrategie wurde heute im Bundeskabinett beraten. Hierdurch soll in Zukunft eine stabile, sichere, nachhaltige und diversifizierte Versorgung mit Wasserstoff und Wasserstoffderivaten ermöglicht werden.

Die wichtigsten Punkte der nun vorgelegten H2-Importstrategie auf einen Blick:

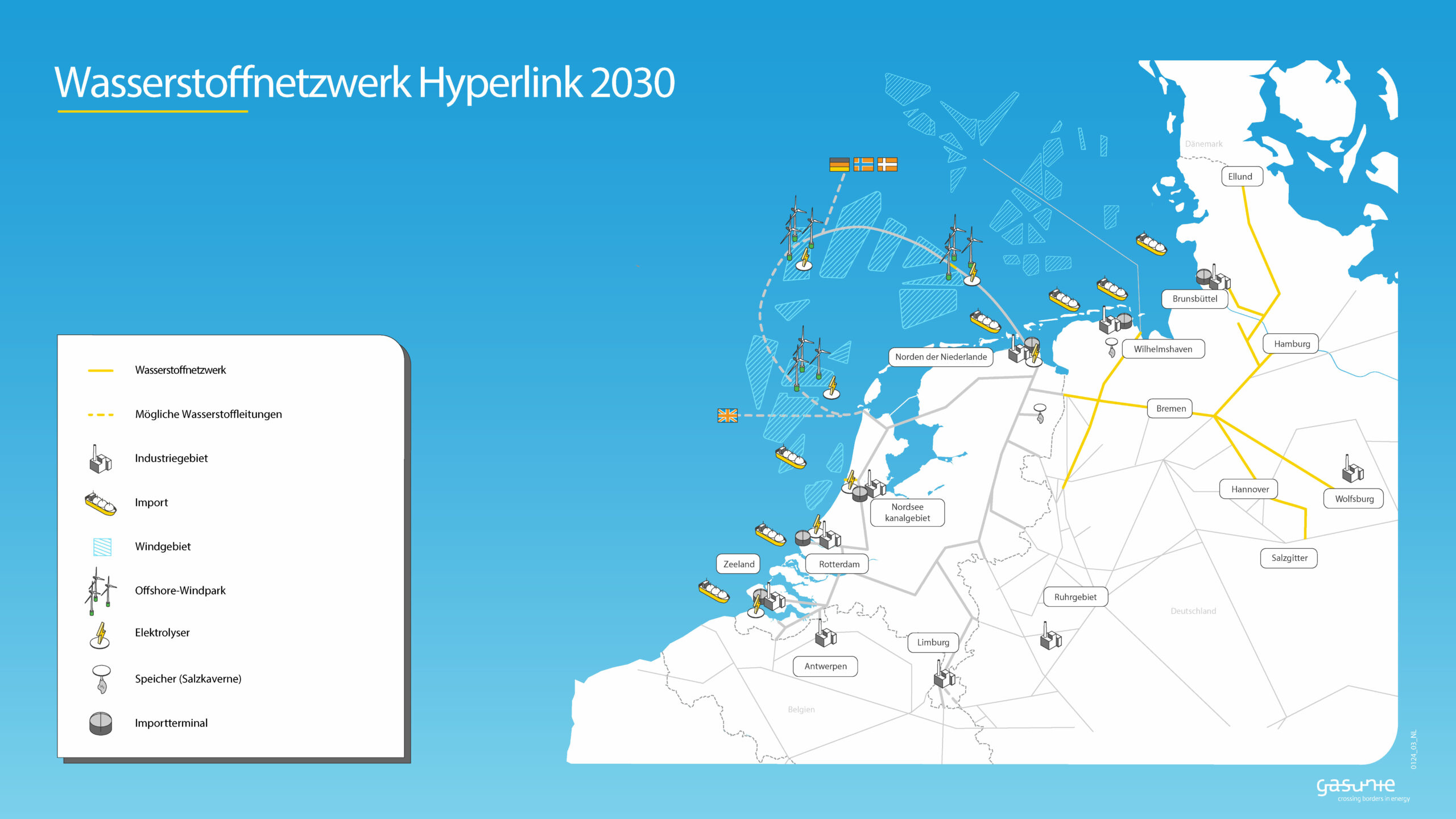

- Der Großteil der Wasserstoffimporte soll aus Kostengründen über Pipelinetransport erfolgen.

- Importierte Wasserstoffderivate sollen per Schiff nach Deutschland transportiert und nach Möglichkeit direkt genutzt werden. Gleichzeitig wird unterstrichen, dass eine Rückumwandlung der Derivate in Wasserstoff für die Bedarfsabdeckung erforderlich sein wird.

- Der Aufbau von pipelinebasierter Importinfrastruktur und Importterminals soll dabei parallel erfolgen.

- Wasserstoff soll kurz- bis mittelfristig per Pipeline und mittel- bis langfristig zusätzlich auch in flüssiger Form per Schiff importiert werden.

- Bei Wasserstoffderivaten setzt die Bundesregierung auf eine Vielzahl von Produkten. Um die Importmengen kurzfristig hochzufahren, sollen vor allem Ammoniak, Methanol und synthetische Kraftstoffe per Schiff und synthetisches Methan per Erdgaspipeline importiert werden.

- Für die Diversifizierung der Lieferquellen kommen eine Vielzahl an Partnerländern und -regionen in Frage, mit denen bereits heute z.T. explizite Wasserstoffabkommen existieren oder gemeinsame Wasserstoffprojekte durchgeführt werden. Hierzu zählen z.B. Norwegen, Namibia, Ägypten und andere.

- Es soll eine Zertifizierung von Wasserstoffimporten geben, um Nachhaltigkeitsstandards und Transparenz über die Eigenschaften der gehandelten Wasserstoffprodukte sicherzustellen

- Die in der Strategie genannten Maßnahmen sollen von zielgerichteten Forschungs- und Entwicklungsmaßnahmen flankiert werden.

Mit der langersehnten Veröffentlichung der Wasserstoffstrategie wird ein weiterer Baustein für den Aufbau und Hochlauf der Wasserstoffwirtschaft gelegt. Die Wasserstoffstrategie hat dabei eine Signalwirkung in zweifacher Hinsicht: Einerseits bietet sie Abnahme- und somit Planungssicherheit für Akteure, die Exportprojekte in Partnerländern realisieren wollen. Andererseits sendet sie auch ein Signal an die deutsche Wirtschaft, dass in Zukunft ausreichend Wasserstoff und Derivate für die Transformation zur Verfügung stehen werden.

Die ganze Strategie finden Sie hier:

Bleiben Sie informiert – mit unserem Newsletter „NWN direkt…“

Sie möchten über diese und andere spannende Wasserstoff-Projekte aus Niedersachsen informiert bleiben? Dann melden Sie sich bei unserem Newsletter an!

Neueste Kommentare