PROJEKTE

Green Wilhelmshaven

Laut Nationaler Wasserstoffstrategie soll der deutsche Wasserstoffbedarf durch eine Kombination aus Eigenproduktion und dem Import von Wasserstoff aus anderen Ländern gedeckt werden. In dem Projekt Green Wilhelmshaven wird dieser Gedanke aufgegriffen, indem der Import von Wasserstoff mittels Ammoniaks im Großmaßstab ermöglicht wird, gleichzeitig jedoch auch grüner Wasserstoff per Elektrolyse vor Ort produziert wird. Hierdurch werden Kapazitäten aufgebaut, die zusammen 10-20 % des Wasserstoff-Bedarfs ganz Deutschlands im Jahr 2030 decken könnten.

News (23.04.2024): Salzgitter AG und Uniper SE unterzeichnen Vorvertrag über die Lieferung und Abnahme von grünem Wasserstoff

Wie die Salzgitter AG und Uniper heute bekanntgaben, haben die beiden Unternehmen einen Vorvertrag über die Lieferung und die Abnahme von grünem Wasserstoff unterzeichnet. Dabei geht es um die Lieferung von bis zu 20.000 Tonnen grünem Wasserstoff pro Jahr nach Salzgitter; die Lieferung könnte laut derzeitiger Planungen ab 2028 erfolgen. Der grüne Wasserstoff soll in einem 200 Megawatt-Elektrolyseur auf dem Gelände des ehemaligen Steinkohlekraftwerks von Uniper in Wilhelmshaven produziert werden. Mehr erfahren

News (06.09.2023): Solarpark in Wilhelmshaven (17 MWp) soll Produktion von grünem Wasserstoff ermöglichen

In Wilhelmshaven errichtet Uniper derzeit einen Solarpark mit einer Leistung von 17 MWp. Der Park soll an die bereits bestehend Netzinfrastruktur an einem Uniper-Standort angeschlossen werden, wodurch auch die Produktion von grünem Wasserstoff am Standort ermöglicht wird. Der Solarpark reiht sich damit in die anderen Aktivitäten im Projekt „Green Wilhelmshaven“ ein. Mehr erfahren

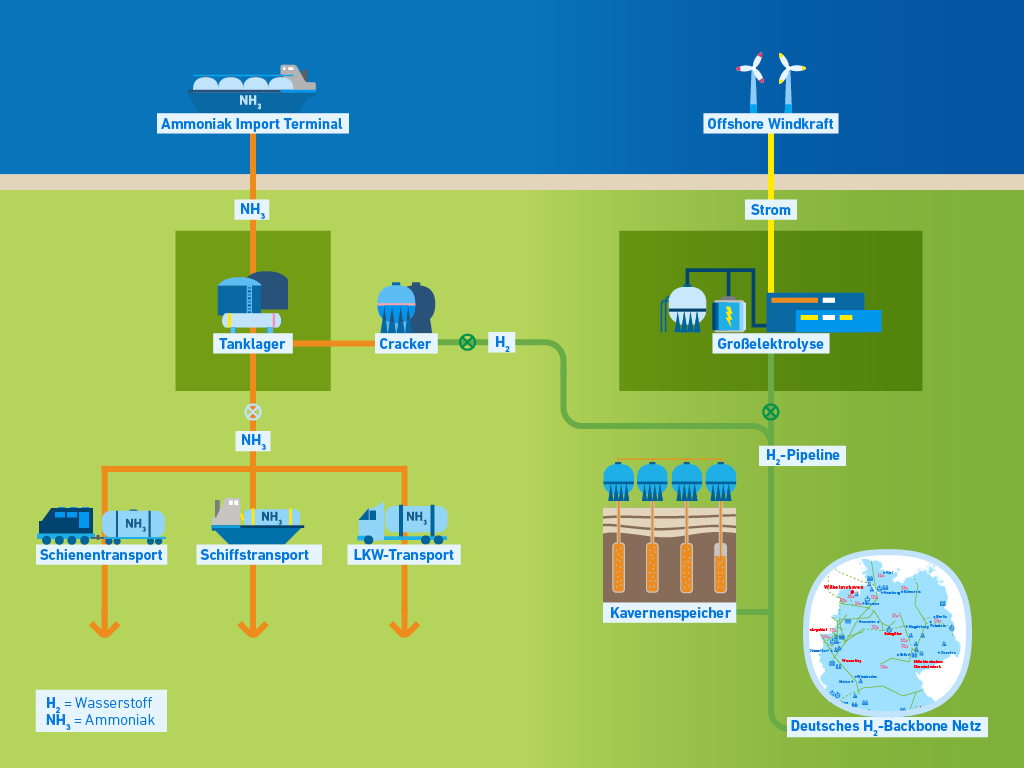

Im Zentrum des Projekts von Uniper steht ein Importterminal für grünes Ammoniak in Wilhelmshaven – inklusive eines sogenannten „Ammoniak-Crackers“, der die Umwandlung von Ammoniak in grünen Wasserstoff und Stickstoff ermöglicht. Grünes Ammoniak kann gut zum Transport von Wasserstoff genutzt werden, da es neben einer hohen Energiedichte auch eine gute Lagerbarkeit besitzt.

Bevor das grüne Ammoniak in Deutschland in Wasserstoff umgewandelt werden kann, muss es im exportierenden Land zunächst jedoch per katalytischer Synthese aus Stickstoff und grünem Wasserstoff hergestellt werden. Anschließend kann es aufgrund der guten Transportfähigkeit z.B. per Schiff nach Wilhelmshaven verschifft und im Ammoniak-Cracker (in der NH3-Spaltanlage) schließlich wieder in grünen Wasserstoff umgewandelt werden. Die Herstellung des Ammoniaks vor dem Transport und die Wiederumwandlung zu Wasserstoff in Deutschland bedeuten jedoch Verluste, die den Gesamtwirkungsgrad reduzieren. Aufgrund der guten Transporteigenschaften kann das grüne Ammoniak aber entscheidend dazu beitragen, die Versorgungssicherheit mit grünem Wasserstoff deutlich zu erhöhen. Die Anlage in Wilhelmshaven soll die erste skalierte Anlage dieser Art in Deutschland werden.

Quelle: Uniper

Quelle: Uniper

Zusätzlich ist im Projekt „Green Wilhelmshaven“ eine Elektrolyse-Anlage in einer Größenordnung von etwa einem Gigawatt geplant. Der erzeugte grüne Wasserstoff soll insbesondere der Versorgung der lokalen Industrie dienen, kann aber auch ins Netz eingespeist werden. Zusammen mit der Wasserstoff-Produktion im „Ammoniak-Cracker“ können laut Planungen schließlich 300.000 Tonnen Wasserstoff erzeugt werden – was ca. 10-20 % des vorgesehenen Wasserstoff-Bedarfs Deutschlands im Jahr 2030 entspricht.

In dem Projekt „Green Wilhelmshaven“ können zudem infrastrukturelle Vorteile der Region genutzt werden, da mit den Salzkavernen in Etzel oder Krummhörn die großtechnische Speicherung von Wasserstoff möglich ist.

Über Uniper

Uniper ist ein internationales Energieunternehmen mit rund 11.500 Mitarbeitenden in mehr als 40 Ländern. Das Unternehmen plant, in der europäischen Stromerzeugung bis 2035 CO2-neutral zu werden. Mit rund 33 Gigawatt installierter Kapazität gehört Uniper zu den größten Stromerzeugern weltweit.

© Uniper

Bleiben Sie informiert – mit unserem Newsletter „NWN direkt…“

Sie möchten über diese und andere spannende Wasserstoff-Projekte aus Niedersachsen informiert bleiben? Dann melden Sie sich bei unserem Newsletter an!