PROJEKTE

Quelle: Bilfinger

Quelle: Bilfinger

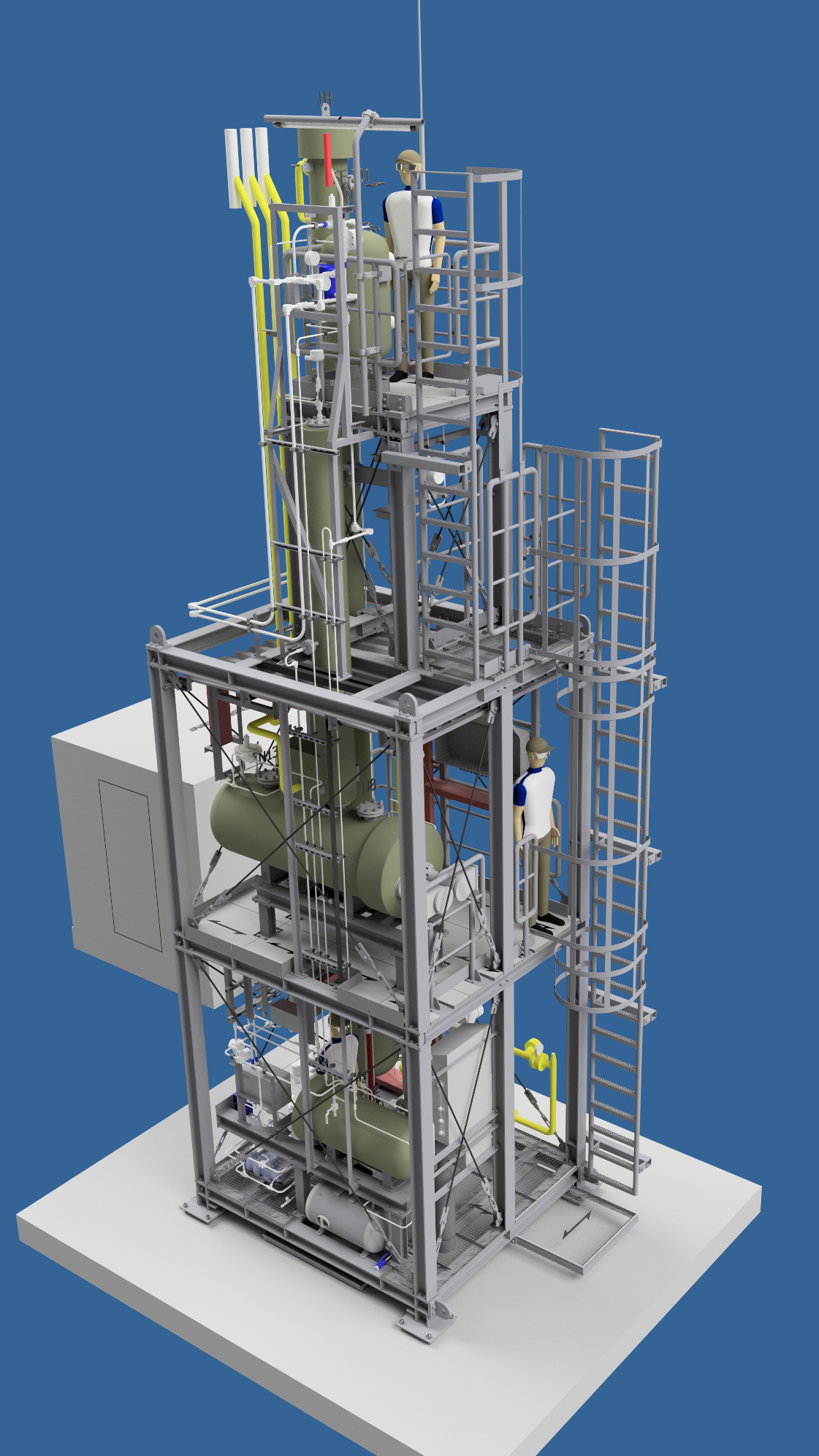

Die Wasserstofftrocknungsanlage von Bilfinger soll die großtechnische Wasserstoffbehandlung ermöglichen.

Dezentrale Wasserstofftrocknung durch Absorption

Die Speicherung von grünem Wasserstoff ist ein zentrales Instrument, um die Versorgungssicherheit mit erneuerbaren Energien zu gewährleisten. Kavernenspeicher können dabei – insbesondere in Niedersachsen – geeignete Speichermöglichkeiten bieten. Um den Wasserstoff jedoch wieder verstromen oder aus den Kavernen ins Leitungsnetz einspeisen zu können, muss dieser zuvor getrocknet werden. Bilfinger entwickelt in diesem Zusammenhang aktuell in Cloppenburg eine Demonstrationsanlage, in welcher der Wasserstoff durch Absorption von Feuchtigkeit befreit wird. Diese sogenannte „Absorptionstrocknung“ wird bereits in großem Maßstab für Erdgas zur Gasspeicherung realisiert – und soll nun auch zur Trocknung großer Mengen Wasserstoffs eingesetzt werden.

News (13.12.2023): Bilfinger unterstützt Uniper bei Wasserstoffspeicher-Projekt in Krummhörn

Uniper untersucht derzeit im niedersächsischen Krummhörn die unterirdische Speicherung von Wasserstoff in einer Salzkaverne. Hierzu wird die Konstruktion und der Betrieb einer Wasserstoff-Testkaverne (3.000 m³) zur unterirdischen Speicherung von Wasserstoff vorangetrieben.

Bilfinger wird das Unternehmen Uniper bei der obertägigen Anlagentechnik der Wasserstoffkaverne mit Engineering-, Beschaffungs- und Baumanagementleistungen (EPCm) unterstützen. Auch die H2DRY-Technologie soll zur Wasserstofftrocknung zum Einsatz kommen. Mehr erfahren

News (26.05.2023): Projekt zur Wasserstoff-Speicherung erreicht nächste Phase: H2dry Anlage von Bilfinger wird am EWE Gasspeicher-Standort in Rüdersdorf aufgebaut

Bilfinger hat in Cloppenburg eine Demonstrationsanlage entwickelt, in welcher der Wasserstoff durch Absorption von Feuchtigkeit befreit wird.

Die sogenannte „H2dry Anlage“ wurde nun zum Gasspeicherstandort der EWE AG nach Rüdersdorf bei Berlin geliefert, wo die Speicherung von Wasserstoff in unterirdischen Kavernen exemplarisch getestet wird. Die Erkenntnisse sollen auf Kavernen mit dem 1.000 fachen Volumen übertragen werden können. Mehr erfahren

Der im Rahmen des Projekts entwickelte Trocknungs-Prozess ermöglicht eine effiziente und großtechnische Wasserstoffbehandlung, die für die Speicherung und anschließende Netzeinspeisung von grünem Wasserstoff essenziell ist. Da die Technologie im Rahmen der Erdgastrocknung bereits erprobt ist, können in der Anlage auch große Mengen Wasserstoff kostengünstig getrocknet werden, welche für den Aufbau der Wasserstoffwirtschaft nötig sind. Nach der Ausspeicherung – zum Beispiel aus Kavernen – wird der Wasserstoff im Rahmen der Absorptionstrocknung mittels einer geeigneten Waschflüssigkeit getrocknet und kann anschließend entweder verstromt oder in das Transportnetz eingespeist werden. Durch die Anlage soll Wasserstoff ähnlich flexibel zur Energieversorgung beitragen können wie Erdgas.

Das gemeinsame Projekt der Bilfinger Engineering & Maintenance GmbH und des Instituts für Thermodynamik der Leibniz Universität Hannover wird vom Land Niedersachen gefördert und ist ein wichtiger Bestandteil der Energiewende, wie der niedersächsische Umweltminister Olaf Lies betont: „Die Umsetzung dieses Projektes ist ein großer Schritt für die Energiewende. Dezentrale Wasserstofftrocknung durch Absorption für Gasspeicher und Netzeinspeisung, ist ein wesentlicher Schritt für die Wasserstoffwirtschaft. Mit dieser Technologie kann der Wasserstoff großtechnisch ökonomisch behandelt werden und das ermöglicht die Integration von Erneuerbaren Energien in unser Energiesystem. So kann der mit Hilfe von Wind- und Solarstrom erzeugte Wasserstoff oder der demnächst in Kavernen gespeicherte Wasserstoff in das Transportnetz eingespeist werden.“

Nach Fertigung bei der Bilfinger Engineering & Maintenance GmbH im niedersächsischen Cloppenburg erfolgt Anfang 2023 eine Testphase sowie ein Demonstrationsbetrieb in Rüdersdorf in Brandenburg, wo die EWE Gasspeicher GmbH aktuell im Rahmen des Projekts HyCAVmobil eine Salzkaverne als potenziellen Speicherort für Wasserstoff untersucht.

Projektbeteiligte

Bilfinger ist ein international tätiger Industriedienstleister. Ziel der Konzerntätigkeit ist es, die Effizienz von Anlagen der Prozessindustrie zu steigern, ihre Verfügbarkeit zu sichern, Emissionen zu reduzieren und die Instandhaltungskosten zu senken. Bilfinger bietet dabei Leistungen in verschiedenen Bereichen an; im Consulting, Engineering, in der Fertigung, Montage und Instandhaltung bis hin zu Umwelttechnologien und digitalen Anwendungen.

Die Bilfinger Engineering & Maintenance GmbH ist Teil des internationalen Bilfinger Konzerns und im Industrieservice tätig. Mehr als 3.000 Mitarbeiterinnen und Mitarbeiter planen und überwachen Anlagen in der Prozessindustrie u.a. in den Bereichen Chemie, Petrochemie und Pharma.

Die Gottfried Wilhelm Leibniz Universität Hannover ist mit rund 30.000 Studierenden Niedersachsens größte Universität. Das Institut für Thermodynamik vertritt die Technische Thermodynamik in der Fakultät für Maschinenbau der Leibniz Universität Hannover in der Lehre und Forschung.

Bleiben Sie informiert – mit unserem Newsletter „NWN direkt…“

Sie möchten über diese und andere spannende Wasserstoff-Projekte aus Niedersachsen informiert bleiben? Dann melden Sie sich bei unserem Newsletter an!